Residential electrical systems demand careful planning and execution, adhering to safety standards like the NEC for reliable power distribution throughout the house.

Understanding the Scope of Home Wiring

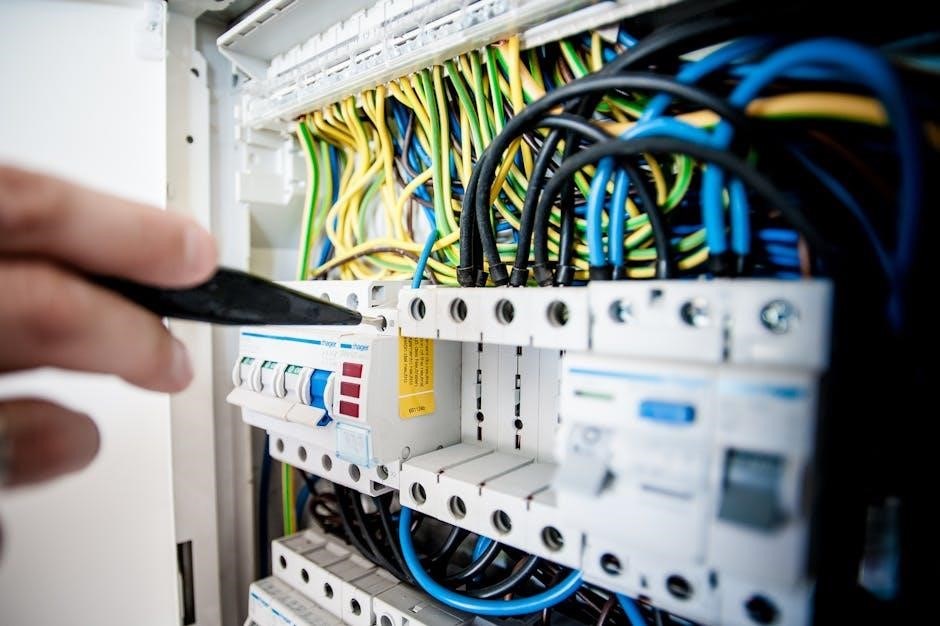

Home electrical wiring encompasses a complex network distributing power from the service panel to outlets, lights, and appliances. This system includes various wiring methods – armored cable, EMT, and nonmetallic tubing – each suited for specific applications. Understanding the scope involves recognizing the different circuit types: general-purpose, dedicated appliance circuits, and specialized circuits for safety devices like smoke detectors;

Proper installation necessitates adherence to the National Electrical Code (NEC), ensuring safety and functionality. The scope extends beyond simply connecting wires; it includes grounding, bonding, and overcurrent protection. Multiconductor cables, fire alarm wiring, and even optical fiber are components within a modern home’s electrical infrastructure, demanding a comprehensive understanding for safe and compliant installations.

Importance of Following Electrical Codes (NEC)

Adhering to the National Electrical Code (NEC) is paramount for residential wiring, safeguarding against fire hazards, electrical shock, and equipment damage. The NEC provides standardized guidelines for safe installation of electrical systems, dictating acceptable wiring methods, component usage, and protection requirements. Ignoring these codes isn’t merely a violation; it compromises the safety of occupants and property.

Compliance ensures proper grounding, overcurrent protection, and appropriate wire sizing for amperage demands. The NEC also specifies requirements for GFCI outlets in kitchens and bathrooms, crucial for preventing electrocution. Following the NEC isn’t optional; it’s a legal and ethical responsibility, often verified through permits and inspections, guaranteeing a secure and reliable electrical system.

Wiring Methods Permitted in Cable Trays

Cable trays support various wiring methods, including armored cable, EMT, and ENT, offering organized routing for electrical conductors within buildings.

Armored Cable (AC) Installation

Armored cable (AC), often referred to as BX cable, provides robust protection for conductors, making it suitable for exposed locations or where physical damage is a concern. Proper installation is crucial for maintaining its protective qualities and ensuring safety. AC cable must be securely fastened to supporting structures using approved fittings and connectors, preventing movement and potential abrasion of the armor.

The armor itself must be bonded to the grounding system at each termination, creating a continuous path for fault current. Avoid sharp bends that can damage the armor, and ensure the cable is adequately supported to prevent sagging; When penetrating metal enclosures, use appropriate bushings to protect the cable from sharp edges. Always consult local electrical codes and the NEC for specific requirements regarding AC cable installation in residential settings, prioritizing safety and compliance.

Electrical Metallic Tubing (EMT) Usage

Electrical Metallic Tubing (EMT), a lightweight and versatile conduit, is widely used in residential electrical systems for protecting conductors. Its ease of bending and cutting makes it adaptable to various installation scenarios. Proper support is essential; EMT must be securely fastened to building structures using straps or clamps at intervals specified by the NEC.

All EMT runs require grounding, achieved through bonding to the electrical system at termination points. When joining sections of EMT, use approved couplings, ensuring a tight and secure connection. Avoid overbending, as this can weaken the conduit. Remember to use appropriate fittings when transitioning between EMT and other components, like boxes or fixtures, maintaining a continuous grounding path throughout the system.

Electrical Nonmetallic Tubing (ENT) Applications

Electrical Nonmetallic Tubing (ENT) offers a cost-effective and lightweight solution for residential wiring, particularly in dry, indoor locations. Its inherent non-conductivity eliminates the need for grounding, simplifying installation. However, ENT requires careful handling to avoid damage during installation, as it’s less robust than metal conduits.

Support spacing is crucial; ENT must be securely fastened with straps or clips at intervals dictated by the NEC. Approved fittings are essential for making connections and transitions. ENT is not permitted in exposed locations subject to physical damage. Always ensure proper bending radius to prevent kinking or stressing the tubing, maintaining its integrity and protecting the enclosed conductors.

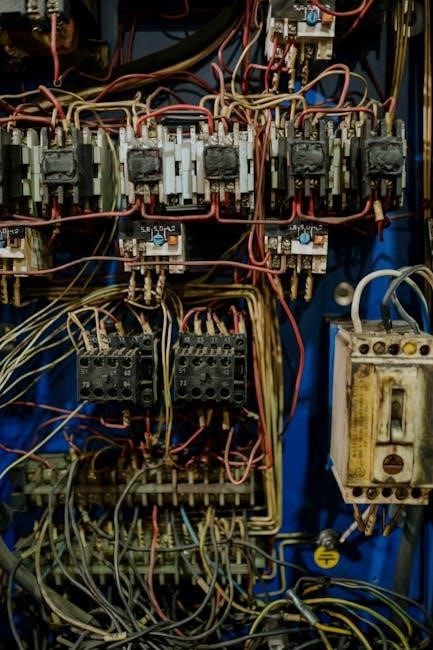

Common Electrical Code Violations

Frequent violations include mismatched wire gauges, improper GFCI outlet installations in kitchens and bathrooms, and crucially, performing electrical work without necessary permits.

Mismatched Wire Gauge and Amperage

Selecting the correct wire gauge is paramount for safety and functionality within a residential electrical system. The National Electrical Code (NEC) meticulously outlines the relationship between wire size and the maximum amperage it can safely conduct. Utilizing a wire gauge incapable of handling the circuit’s amperage creates a significant fire hazard due to overheating.

Undersized wiring presents a substantial risk, potentially leading to melted insulation, arcing, and ultimately, electrical fires. Conversely, oversizing isn’t necessarily harmful but represents an unnecessary expense. Always consult the NEC tables to determine the appropriate wire gauge based on the circuit’s amperage rating and length. Matching these specifications is non-negotiable for a compliant and secure electrical installation.

Faulty GFCI Outlet Installation

Ground Fault Circuit Interrupter (GFCI) outlets are crucial safety devices designed to protect against electrical shock, particularly in damp locations. Improper installation negates their protective function, creating a dangerous situation. Common errors include incorrect wiring – misidentifying line and load terminals – and failing to adequately secure the outlet within the electrical box.

Furthermore, GFCIs must be installed in areas mandated by the NEC, such as kitchens and bathrooms. A frequent violation is omitting GFCIs where required or installing them incorrectly. Regular testing, using the built-in test and reset buttons, is essential to verify functionality. Ensuring proper installation and consistent testing are vital for safeguarding against electrical hazards and maintaining code compliance.

GFCI Outlet Requirements in Kitchens

Kitchens present a high-risk environment for electrical shock due to the combination of water and electrical appliances. The National Electrical Code (NEC) mandates GFCI protection for all 120-volt through 250-volt receptacles serving kitchen countertop surfaces. This includes receptacles installed within countertops, as well as those located within a specific distance of sinks.

Specifically, GFCI protection extends to all outlets serving the countertop areas. This requirement aims to minimize the risk of electrocution from faulty appliances or accidental contact with water. Proper installation and regular testing of these GFCIs are paramount. Ignoring these requirements constitutes a significant code violation and compromises safety within the kitchen environment.

GFCI Outlet Requirements in Bathrooms

Bathrooms, like kitchens, are considered wet locations, necessitating stringent electrical safety measures. The NEC requires GFCI protection for all 120-volt through 250-volt receptacles installed within bathroom spaces. This encompasses receptacles serving the countertop areas, as well as those located near sinks and bathtubs.

GFCI protection is crucial to prevent electrical shock hazards arising from the proximity of water and electrical devices. Outlets must be appropriately grounded and installed according to code. Regular testing of GFCI functionality is essential to ensure continued protection. Failure to comply with these regulations represents a serious safety concern and a code violation, potentially leading to severe consequences.

Lack of Permits and Inspections

Many residential electrical projects necessitate obtaining permits from local authorities before commencing work. These permits ensure that the planned installation adheres to the National Electrical Code (NEC) and local amendments, safeguarding against potential hazards. Skipping this step is a frequent violation.

Subsequent inspections are equally vital. A qualified electrical inspector verifies that the work was completed safely and correctly, confirming compliance with established standards. Ignoring inspections leaves homeowners vulnerable to undetected errors, increasing the risk of fire or electrical shock. Proper documentation and adherence to the permitting process are crucial for a safe and legally compliant electrical system.

NM Cable Installation Best Practices

Secure NM cable properly using staples, maintaining appropriate spacing from both metal and plastic boxes to prevent damage and ensure a safe installation.

Securing NM Cable with Staples

Properly securing Nonmetallic-Sheathed (NM) cable is crucial for a safe and code-compliant electrical installation. Staples designed for this purpose must be utilized, ensuring they don’t damage the cable’s insulation. The NEC dictates specific staple spacing requirements based on box material.

Maintaining correct distances prevents cable stress and potential shorts. Improperly secured cables can become loose, creating a fire hazard or interrupting electrical flow. Careful attention to these details is paramount during installation. Always prioritize safety and adherence to established electrical codes.

Consistent and correct stapling demonstrates a commitment to quality workmanship and long-term reliability of the electrical system within the residence.

Staple Spacing from Metal Boxes

When securing NM cable near metal boxes, the National Electrical Code (NEC) mandates a maximum staple spacing of 12 inches. This requirement is specifically tied to installations utilizing NM cable clamps within the metal box. The clamps provide additional support and protection for the cable as it enters the enclosure.

This spacing ensures the cable remains firmly in place, preventing movement or strain that could compromise the insulation. Adhering to this rule minimizes the risk of short circuits or electrical hazards. Proper installation is vital for safety and code compliance.

Consistent application of this 12-inch rule demonstrates a thorough understanding of electrical best practices and a commitment to a secure installation.

Staple Spacing from Plastic Boxes

For NM cable installations near plastic boxes, the NEC dictates a closer staple spacing than with metal boxes. A maximum distance of 8 inches between staples is required when NM cable is secured to a plastic box without cable clamps. This reduced spacing is crucial because plastic boxes offer less inherent support compared to their metal counterparts.

The tighter staple spacing compensates for the lack of clamping, ensuring the cable is adequately secured and protected from physical damage. This prevents sagging, chafing, or potential insulation breaches.

Strict adherence to this 8-inch rule is paramount for maintaining a safe and code-compliant electrical system, particularly when utilizing plastic enclosures.

NM Cable Bend Radius Restrictions

Maintaining proper bend radius for Nonmetallic-Sheathed (NM) cable is critical to prevent damage to the insulation and ensure long-term reliability. The NEC specifies that NM cable bends should not be sharper than five times the cable’s diameter. This rule safeguards against kinking or stressing the conductors within the cable.

Excessive bending can compromise the insulation, potentially leading to short circuits or ground faults. Sharp bends create stress points, increasing the risk of insulation breakdown over time.

Adhering to the 5D rule (where D represents the cable diameter) is a fundamental practice for safe and code-compliant NM cable installations, preserving the cable’s integrity.

Residential Electrical Inspections ⎻ Key Areas

Inspections verify proper receptacle placement, ensuring no outlets are located above electric baseboard heaters, and confirm secure NM cable installations for safety.

Receptacle Outlet Placement Restrictions

Residential electrical codes dictate specific rules regarding receptacle outlet placement to enhance safety and functionality within a home. A critical restriction involves prohibiting the installation of receptacle outlets directly above electric baseboard heaters; this prevents potential overheating and fire hazards due to obstructed heat dissipation.

Furthermore, outlets near wet locations, such as kitchens and bathrooms, require Ground Fault Circuit Interrupter (GFCI) protection. Inspectors meticulously check for adherence to these requirements, ensuring GFCI outlets are correctly installed and functioning in all designated areas.

Spacing requirements also apply, mandating outlets be accessible and conveniently located throughout living spaces to minimize the use of extension cords, which can pose tripping hazards and overload circuits. Proper placement is paramount for a safe and compliant electrical system.

Inspection Focus on NM Cable Security

Electrical inspections heavily scrutinize the secure installation of Nonmetallic-Sheathed cable (NM cable), a common wiring method in residential settings. Inspectors verify that NM cable is properly secured with staples designed to avoid damaging the cable’s insulation.

Specific attention is given to staple spacing; a maximum distance of 12 inches from metal boxes utilizing cable clamps, and 8 inches from plastic boxes without clamps, is strictly enforced.

Furthermore, inspectors assess the bend radius of NM cable, ensuring it doesn’t exceed five times the cable diameter to prevent insulation stress and potential shorts. A secure and correctly installed NM cable run is crucial for preventing electrical hazards and ensuring long-term system reliability, making it a key inspection point.

Safety Precautions During Electrical Work

Always de-energize circuits before commencing any work, and utilize appropriate Personal Protective Equipment (PPE) like insulated gloves and safety glasses for protection.

De-energizing Circuits Before Work

Prior to initiating any electrical work, complete de-energization of the relevant circuits is paramount for safety. This involves switching off the corresponding circuit breaker or removing the fuse at the electrical panel. Never assume a circuit is de-energized; always verify with a reliable voltage tester to confirm the absence of electrical current.

Lockout/Tagout procedures should be implemented, especially in multi-worker environments, to prevent accidental re-energization. This involves physically locking the breaker in the off position and attaching a tag indicating that work is in progress. Double-check all connections and wiring before restoring power, ensuring everything is properly insulated and secured. Ignoring this crucial step can lead to severe injury or even fatality.

Using Proper Personal Protective Equipment (PPE)

Electrical work necessitates the consistent use of appropriate Personal Protective Equipment (PPE) to minimize the risk of injury. Insulated gloves, rated for the voltage being worked with, are essential for protecting hands from electrical shock. Safety glasses or face shields safeguard eyes from arc flashes and flying debris.

Flame-resistant clothing (FRC) provides an added layer of protection against burns. Insulated footwear prevents electrical current from grounding through the body. Avoid wearing metallic jewelry or clothing, as these can conduct electricity. Regularly inspect PPE for damage and replace it when necessary. Proper PPE isn’t merely a recommendation; it’s a critical component of safe electrical practices.

Resources for Electrical Wiring Information

Accessing the NEC Handbook and OSHA guidelines provides crucial, up-to-date information for safe and compliant residential electrical wiring practices and standards.

National Electrical Code (NEC) Handbook

The NEC Handbook is an indispensable resource for anyone involved in electrical work, offering detailed explanations and interpretations of the National Electrical Code (NEC) requirements. It’s not simply a restatement of the code itself, but provides background information, examples, and reasoning behind the rules.

Understanding the NEC is paramount for ensuring electrical installations are safe, compliant, and function correctly. The handbook clarifies complex regulations concerning wiring methods, component selection, and safety measures. It assists in navigating the often-detailed stipulations regarding cable types like Armored Cable (AC), Electrical Metallic Tubing (EMT), and Nonmetallic-Sheathed Cable (NM).

Furthermore, the NEC Handbook aids in interpreting rules related to Ground Fault Circuit Interrupter (GFCI) outlet placement and proper installation, crucial for preventing electrical shock hazards in kitchens and bathrooms. Regularly consulting the NEC Handbook is vital for staying current with code updates and best practices.

Occupational Safety and Health Administration (OSHA) Guidelines

OSHA guidelines are critical for safeguarding workers during electrical installations and maintenance, establishing mandatory safety standards to minimize workplace hazards. Specifically, 1910.305 outlines permissible wiring methods for cable tray systems, including armored cable, EMT, and nonmetallic tubing, ensuring safe cable management.

These regulations emphasize de-energizing circuits before commencing any work, a fundamental safety precaution to prevent electrocution. Proper use of Personal Protective Equipment (PPE), such as insulated gloves and safety glasses, is also mandated.

OSHA’s focus extends to ensuring correct wiring component usage and adherence to the NEC, promoting a secure electrical environment. Compliance with OSHA standards isn’t just a legal requirement; it’s a commitment to worker well-being, preventing injuries and fatalities associated with electrical hazards.