What is Risograph: A Comprehensive Guide (Updated November 2nd‚ 2026)

Risograph‚ often shortened to Riso‚ is a digital duplicator offering a unique aesthetic.

Bang Bang Zine shop‚ a Kuala Lumpur haven‚ showcases its vibrant potential within zine culture and DIY publishing.

Risograph printing represents a fascinating intersection of analog and digital technologies‚ offering a distinctive aesthetic that sets it apart from conventional printing methods. Unlike inkjet or laser printers‚ the Risograph doesn’t rely on transferring toner to paper. Instead‚ it functions as a stencil duplicator‚ creating prints with a tactile quality and vibrant‚ slightly imperfect color separations.

This process‚ popularized by independent artists‚ zine creators‚ and small businesses‚ has experienced a significant resurgence in recent years. The Bang Bang Zine shop in Kuala Lumpur exemplifies this thriving community‚ acting as a hub for Riso enthusiasts and showcasing the diverse range of possibilities this technology unlocks.

Risograph’s appeal lies in its affordability‚ speed‚ and unique visual characteristics. It’s a method that embraces happy accidents‚ resulting in prints with a textured feel and a charmingly handmade appearance. It’s more than just printing; it’s a creative process that encourages experimentation and celebrates individuality.

What is a Risograph Machine?

A Risograph machine‚ manufactured by Riso Kagaku Corporation‚ is a high-speed digital duplicator utilizing a unique stencil-based printing process. It’s not a traditional printer; instead‚ it creates a master from digital artwork‚ then uses that master to print multiple copies quickly and efficiently. Think of it as a sophisticated mimeograph‚ but digitally controlled.

The machine itself consists of a drum‚ an ink system‚ and a paper feed. The drum creates the stencil‚ the ink is oil-based and highly pigmented‚ and the paper feed handles the printing process. Unlike laser printers‚ Risographs use spot colors – meaning each color requires a separate stencil and pass.

Places like the Bang Bang Zine shop in Kuala Lumpur rely on these machines to produce zines and art prints. They are known for their durability‚ speed‚ and relatively low running costs‚ making them ideal for medium to high-volume print runs‚ especially within independent publishing circles.

The History of Risograph Technology

Risograph technology emerged in Japan in the 1980s‚ developed by Riso Kagaku Corporation as a more affordable and efficient alternative to traditional offset printing. Initially designed for in-house printing in businesses and schools‚ it quickly gained traction due to its speed and low per-print cost.

The core innovation was the creation of a thermal transfer stencil. This stencil‚ created from digital artwork‚ allowed for quick duplication without the lengthy setup times associated with screen printing or offset. Early models were monochrome‚ but color capabilities were gradually added over the years.

The technology found a strong foothold in the zine and independent publishing communities‚ particularly in the 1990s and 2000s. Shops like Bang Bang Zine in Kuala Lumpur exemplify this continued use. Its affordability and distinctive aesthetic made it a favorite among artists and DIY enthusiasts‚ fostering a unique print culture.

How Risograph Printing Works: A Step-by-Step Process

Risograph printing begins with digital artwork sent to the machine. The Riso creates a thermal stencil – a paper sheet with tiny perforations corresponding to the image. This happens by exposing the stencil paper to heat based on the artwork data.

Next‚ a drum coated with ink rotates‚ and the ink passes through the perforations onto the paper. Each color requires a separate stencil and drum rotation. This layering process is key to the Riso’s unique look. The machine efficiently duplicates prints‚ making it cost-effective for larger runs.

The process differs significantly from digital or offset printing. Like Bang Bang Zine shop demonstrates‚ the hands-on nature and distinct results appeal to artists. Finally‚ prints are collated‚ and the stencils are discarded after use‚ contributing to its unique characteristics.

Risograph vs. Digital Printing: Key Differences

Digital printing‚ like laser or inkjet‚ directly transfers images from computer to paper‚ offering full-color gradients and photographic detail. Risograph‚ however‚ utilizes stencils and drum rotation‚ resulting in a more textured‚ graphic aesthetic. While digital excels in variable data and short runs‚ Riso shines with mid-length print jobs.

Color reproduction differs significantly. Digital achieves a wider color gamut‚ while Riso’s limited palette (typically 15 colors) creates unique‚ often slightly misregistered‚ effects. This imperfection is a hallmark of the Riso style‚ celebrated by communities like those frequenting Bang Bang Zine shop.

Cost-effectiveness also varies. Digital is cheaper for small quantities‚ but Riso becomes more economical with increasing volume. Ultimately‚ the choice depends on the desired look‚ budget‚ and print run length.

Risograph vs. Screen Printing: A Comparison

Screen printing‚ a traditional method‚ forces ink through a mesh stencil onto paper‚ known for its vibrant‚ opaque colors and durability. Risograph‚ while also stencil-based‚ employs a digital process‚ creating a different aesthetic. Screen printing is ideal for bold designs on various substrates‚ while Riso excels in layered‚ graphic imagery.

A key difference lies in setup. Screen printing requires creating a separate stencil for each color‚ making it labor-intensive for multi-color prints. Risograph utilizes digital separation‚ streamlining the process. This efficiency is appreciated by zine creators‚ often seen at places like Bang Bang Zine shop.

Cost-wise‚ screen printing can be expensive for short runs due to setup fees. Riso offers a more affordable option for mid-length prints. Both methods offer unique textures and artistic possibilities‚ catering to different creative needs.

Risograph Ink Characteristics

Risograph inks are distinctly different from typical printing inks. They’re oil-based‚ creating a unique texture and slightly grainy appearance‚ contributing to the signature Riso aesthetic. Unlike digital printing’s smooth finish‚ Riso prints possess a tactile quality‚ often celebrated in zine culture‚ as showcased at shops like Bang Bang Zine shop.

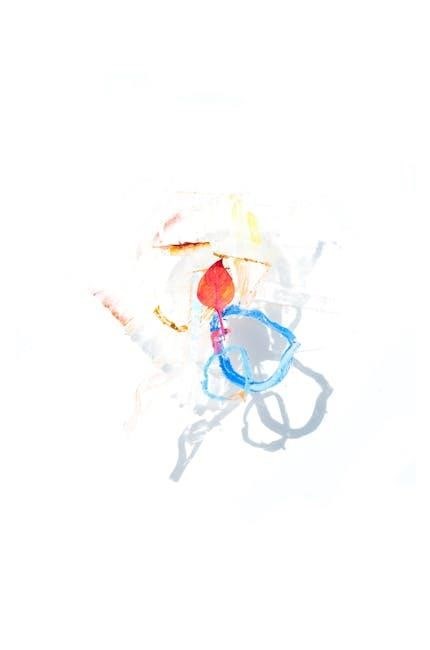

The ink isn’t printed as a solid layer; instead‚ it’s deposited as tiny dots‚ resulting in a semi-opaque effect. This characteristic influences color blending and layering possibilities. Colors don’t mix in the traditional sense‚ but rather create interesting moiré patterns when overlapped.

Riso inks also exhibit a degree of transparency‚ meaning underlying layers can subtly influence the final color. This requires careful consideration during color separation and design. The ink’s viscosity and drying time also play a role in print quality and potential effects.

Types of Risograph Ink Available

Risograph inks come in a surprisingly diverse range‚ though not as extensive as those for conventional printing. The standard palette typically includes black‚ cyan‚ magenta‚ and yellow – the foundational CMYK colors. These are the most commonly used‚ particularly for full-color reproductions‚ and are readily available from most suppliers.

Beyond CMYK‚ a selection of spot colors expands creative possibilities. Popular choices include fluorescent pink‚ orange‚ green‚ and blue‚ offering vibrant accents and unique visual effects. These spot colors are often favored within the zine community‚ exemplified by the diverse offerings at Bang Bang Zine shop.

Metallic silver and gold inks are also available‚ adding a premium touch to prints. However‚ these require specific drum considerations and may necessitate adjustments to the printing process. Specialty inks‚ like white‚ are less common but can be used for underprinting or creating unique effects on colored paper.

Risograph Paper Compatibility

Risograph machines aren’t as finicky about paper as some printing methods‚ but compatibility is crucial for optimal results. Generally‚ Risographs handle a wide range of paper weights‚ typically between 50gsm and 216gsm. Lighter weights are ideal for zines and flyers‚ while heavier stocks suit posters and covers.

Smooth‚ uncoated papers are the sweet spot‚ allowing the ink to sit beautifully on the surface and showcase the characteristic Risograph texture. Coated papers can cause issues with ink adhesion and drying. Textured papers can also yield interesting effects‚ but require testing.

The vibrant zine selection at Bang Bang Zine shop demonstrates the versatility of Risograph on various paper types. Recycled papers are a popular‚ eco-friendly choice‚ aligning with the DIY ethos. Avoid papers with excessive dust or debris‚ as this can clog the machine’s delicate mechanisms.

Best Paper Stocks for Risograph Printing

Selecting the right paper dramatically impacts the final Risograph print. For zines and projects prioritizing affordability‚ 70-90gsm text weight papers are excellent choices. These offer a good balance between cost and durability‚ frequently seen in the diverse collection at Bang Bang Zine shop.

For covers or projects demanding a more substantial feel‚ consider 120-160gsm card stocks. These provide increased rigidity and a premium aesthetic. Japanese papers‚ like Kitakata‚ are highly sought after for their unique texture and ability to showcase the Riso’s ink beautifully.

Recycled papers‚ available in various weights‚ are a sustainable option. Experimentation is key! Tomoe River paper‚ despite being thin‚ is renowned for its smoothness and ink hold. Always test a small batch before committing to a large print run to ensure compatibility and desired results.

The Aesthetic Qualities of Risograph Prints

Risograph printing possesses a distinctive aesthetic‚ diverging significantly from digital or screen printing. A hallmark is its slightly imperfect‚ tactile quality – a deliberate departure from sterile perfection. This charm is readily apparent when browsing the zines at Bang Bang Zine shop‚ each possessing a unique character.

The process creates subtle misalignments and variations in ink density‚ contributing to a handmade feel. Colors are vibrant yet possess a slightly grainy texture‚ often described as retro or vintage. Solid areas of color aren’t perfectly solid‚ exhibiting a beautiful‚ organic pattern.

Layering colors through overprinting results in unique blends and unexpected hues. This inherent unpredictability is part of the appeal‚ fostering creativity and embracing imperfections. The aesthetic is often described as raw‚ energetic‚ and visually engaging‚ making it ideal for artistic expression.

Common Risograph Effects & Characteristics

Risograph printing exhibits several characteristic effects stemming from its unique process. Misregistration‚ a slight misalignment of colors‚ is common‚ creating a textured‚ layered look often celebrated for its handmade quality – visible in the zines at Bang Bang Zine shop.

Halftone patterns are prominent‚ particularly in gradients‚ resulting in a distinct dot-matrix appearance. This isn’t a flaw‚ but a defining feature. Ink bleed can occur‚ especially with finer details‚ adding to the organic feel. Color shifts are also typical‚ as each color is printed separately‚ potentially leading to slight variations.

The machine’s drum system can create subtle banding in solid areas. These aren’t defects‚ but inherent characteristics. Risograph excels at bold‚ graphic designs‚ and limited color palettes. The process favors strong contrasts and simple shapes‚ enhancing its distinctive aesthetic. Embracing these effects is key to successful Riso printing.

Risograph Color Separation Explained

Risograph printing utilizes a unique color separation process‚ differing significantly from traditional CMYK. Each color in your artwork requires a separate master created by the machine‚ essentially creating a stencil for each hue. This means a four-color design needs four individual print runs‚ one for each color layer.

Unlike digital printing which blends colors‚ Riso builds them up through overprinting. This is why designs are often broken down into flat colors‚ avoiding complex gradients. The process is akin to screen printing‚ but automated. The zines showcased at Bang Bang Zine shop demonstrate this beautifully.

Understanding this separation is crucial for artwork preparation. Colors won’t blend on the machine; they’ll sit on top of each other. Transparency and blending modes behave differently than in digital software. Careful planning and color choices are essential to achieve the desired results with Risograph.

Creating Artwork for Risograph: Design Considerations

Designing for Risograph demands a shift in mindset from typical digital workflows. Embrace flat colors and avoid gradients‚ as the machine lays down each color as a distinct layer. Transparency effects require careful consideration; they don’t blend like in Photoshop. Think about how colors will interact when overprinted – the zines at Bang Bang Zine shop exemplify this.

Line art and bold shapes thrive in Risograph printing. Consider the limitations of color separation; each color needs its own stencil. Simplify your designs and minimize the number of colors to reduce costs and maintain clarity. Vector graphics are generally preferred for clean lines and scalability.

Remember that registration isn’t always perfect. Slight misalignments can add to the charm‚ but excessive movement can ruin a print. Test your artwork with proofs to anticipate the final result and adjust accordingly. Risograph rewards intentional design choices.

Risograph Printing Costs: A Breakdown

Risograph printing costs are influenced by several key factors. The primary expense is typically per-print cost‚ which includes the price of paper and the ink used for each color layer. More colors directly translate to higher costs‚ as each requires a separate stencil and ink run. Bang Bang Zine shop‚ like other services‚ will factor this in.

Setup fees are common‚ covering the time to create stencils and calibrate the machine for your specific artwork. Paper choice also impacts the price; specialty stocks are more expensive than standard options. Run length significantly affects the per-print cost – larger runs benefit from economies of scale.

Finally‚ consider finishing options like trimming‚ folding‚ or binding. Expect to pay extra for these services. Generally‚ Risograph is cost-effective for medium-sized runs‚ offering a balance between quality and affordability compared to other methods.

Finding a Risograph Printing Service

Locating a Risograph printing service requires some research‚ as it’s not as ubiquitous as digital or offset printing. Online directories specializing in alternative printing methods are a good starting point. Search terms like “Risograph printing near me” will yield local options.

Consider services that cater to zine culture and independent artists‚ as they often have Risograph capabilities. Bang Bang Zine shop in Kuala Lumpur is a prime example of a dedicated space. Check their websites for pricing‚ paper stock options‚ and file preparation guidelines.

When evaluating services‚ request quotes from multiple providers‚ detailing your project specifications – run length‚ number of colors‚ paper type‚ and finishing requirements. Review their portfolios to assess the quality of their work and ensure it aligns with your aesthetic vision. Don’t hesitate to ask about their experience with similar projects.

Risograph in Zine Culture & DIY Publishing

Risograph printing has become deeply intertwined with zine culture and the DIY publishing world‚ offering an accessible and affordable alternative to mainstream printing methods. Its unique aesthetic – imperfect registration‚ textured ink‚ and limited color palettes – perfectly complements the raw‚ handmade feel often sought by zine creators.

The relatively low cost per print‚ especially for larger runs‚ makes Risograph ideal for self-funded projects. Spaces like Bang Bang Zine shop in Kuala Lumpur actively foster this community‚ providing access to equipment and a platform for independent artists.

Risograph empowers creators to bypass traditional publishing gatekeepers‚ fostering a spirit of self-expression and experimentation. The process encourages thoughtful design choices‚ embracing limitations rather than striving for flawless reproduction. This ethos resonates strongly within the zine community‚ valuing authenticity and artistic vision above all else.

Bang Bang Zine Shop & the Risograph Community

Bang Bang Zine shop‚ nestled within Kuala Lumpur’s GMBB creative community mall‚ stands as a vibrant hub for Risograph enthusiasts and independent publishers. More than just a retail space‚ it’s a testament to the growing Risograph community and the power of DIY culture.

One half of the shop is dedicated to a curated selection of zines‚ showcasing the diverse range of artistic expression achievable with Risograph technology. The other half houses their Risograph printing services‚ making the technology accessible to artists who may not have the resources to invest in their own machine.

Bang Bang actively cultivates a collaborative environment‚ hosting workshops and events that connect artists and foster knowledge-sharing. It’s a place where experimentation is encouraged‚ and the unique qualities of Risograph printing are celebrated‚ solidifying its role as a cornerstone of the regional zine scene.

Risograph Machine Maintenance & Troubleshooting

Maintaining a Risograph machine is crucial for consistent print quality and longevity. Regular cleaning of the drum‚ master roller‚ and ink pathways prevents build-up that can cause smudging or inconsistent color. The master roller‚ vital for image transfer‚ requires periodic replacement as it wears down with use.

Common troubleshooting issues include paper jams‚ often caused by incorrect paper type or feed adjustments. Ghosting‚ where faint images appear‚ can indicate a worn drum or insufficient ink. Streaking usually points to a dirty or damaged master roller. Addressing these promptly prevents further damage.

Understanding the machine’s mechanics and consulting the user manual are essential. Bang Bang Zine shop‚ with its expertise‚ often provides guidance to the community. Proactive maintenance‚ coupled with quick issue resolution‚ ensures a reliable and vibrant Risograph printing experience.

Popular Risograph Machine Models

Several Risograph models cater to diverse printing needs‚ from small-scale zine production to larger commercial projects. The Riso GR3700 is a widely used workhorse‚ known for its reliability and versatility‚ handling various paper stocks and ink colors effectively.

The Riso MZ1090 is a popular choice for single-color printing‚ favored by zine makers and artists for its affordability and ease of use. For higher volume and more complex projects‚ the Riso ComColor GD9630 offers advanced features and faster printing speeds.

Bang Bang Zine shop‚ a hub for Risograph enthusiasts‚ often utilizes and demonstrates various models. Newer models like the Riso SF9350 incorporate improved automation and digital workflow integration. Choosing the right model depends on budget‚ print volume‚ and desired features.

The Future of Risograph Printing

The future of Risograph printing appears bright‚ fueled by a growing appreciation for its unique aesthetic and sustainable qualities. While digital printing dominates‚ Riso’s tactile and imperfect charm resonates with artists and designers seeking alternatives to mass-produced perfection.

Innovations in ink formulations and paper compatibility are expanding the creative possibilities. Expect to see more hybrid workflows‚ integrating digital design tools with the Riso process. The community‚ exemplified by spaces like Bang Bang Zine shop‚ will continue to drive experimentation and knowledge sharing.

Increased accessibility through smaller‚ more affordable machines and online resources will further democratize the technology. A focus on eco-friendly practices and reduced waste positions Risograph as a responsible printing choice for a conscious generation.

Resources for Risograph Artists & Printers

For aspiring and established Risograph artists‚ a wealth of resources exists to support their creative journey. Online communities and forums provide platforms for sharing knowledge‚ troubleshooting‚ and showcasing work. Websites dedicated to Riso printing offer tutorials‚ technical guides‚ and inspiration.

Bang Bang Zine shop in Kuala Lumpur serves not only as a retail space but also as a hub for the local Risograph community‚ often hosting workshops and events. Numerous printing services worldwide specialize in Riso‚ offering expertise and access to equipment.

Software tutorials focusing on color separation and file preparation are readily available. Exploring zine fairs and independent publishing events provides opportunities to connect with fellow artists and learn from experienced printers. Dedicated Instagram accounts and blogs curate inspiring Riso projects and share valuable tips.

Risograph Software & File Preparation

Preparing artwork for Risograph printing demands specific considerations due to the machine’s unique process. Unlike standard CMYK workflows‚ Riso printing relies on spot colors‚ requiring artwork to be separated into individual layers – one for each color intended in the final print.

Adobe Photoshop and Illustrator are commonly used for this separation process‚ though dedicated Riso software options are emerging. These tools allow artists to define each color as a distinct layer‚ ensuring accurate reproduction on the machine. Vector graphics are generally preferred for cleaner results.

Understanding the limitations of the Riso process is crucial. Fine details and gradients may not translate perfectly‚ and registration can have slight variations. Careful planning and experimentation are key to achieving desired outcomes. Resources from printing services and online tutorials can guide this preparation.

Environmental Impact of Risograph Printing

Risograph printing presents a comparatively lower environmental impact than many other printing methods. The machine utilizes soy-based inks‚ a renewable resource‚ significantly reducing reliance on petroleum-based alternatives common in conventional printing. This contributes to lower VOC (Volatile Organic Compounds) emissions.

Furthermore‚ the Risograph’s energy consumption is notably less than digital or offset printing. Its operational simplicity and lack of heat-intensive processes translate to a smaller carbon footprint. The machine’s durability also extends its lifespan‚ reducing the need for frequent replacements.

However‚ paper consumption remains a factor. While Riso encourages mindful material choices‚ responsible sourcing and recycled paper options are vital for maximizing its eco-friendly potential. The vibrant zine community‚ like that fostered at Bang Bang Zine shop‚ often prioritizes sustainable practices.